- Fast delivery

- Large assortment

- 30 days return policy

- Secure payment

Overhaul workshop

Passion for engineering

2CV Overhaul workshop & 2CV Tuning

Burton Car Company has the best 2CV overhaul workshop in the world. Under our brand name 'Burton 2CV parts', we recondition various 2CV parts, including 2CV engines, 2CV gearboxes, 2CV crankshafts, 2CV camshafts, 2CV brake calipers, 2CV brake drums, 2CV cylinder heads, 2CV steering boxes, 2CV front ends and 2CV rear ends.

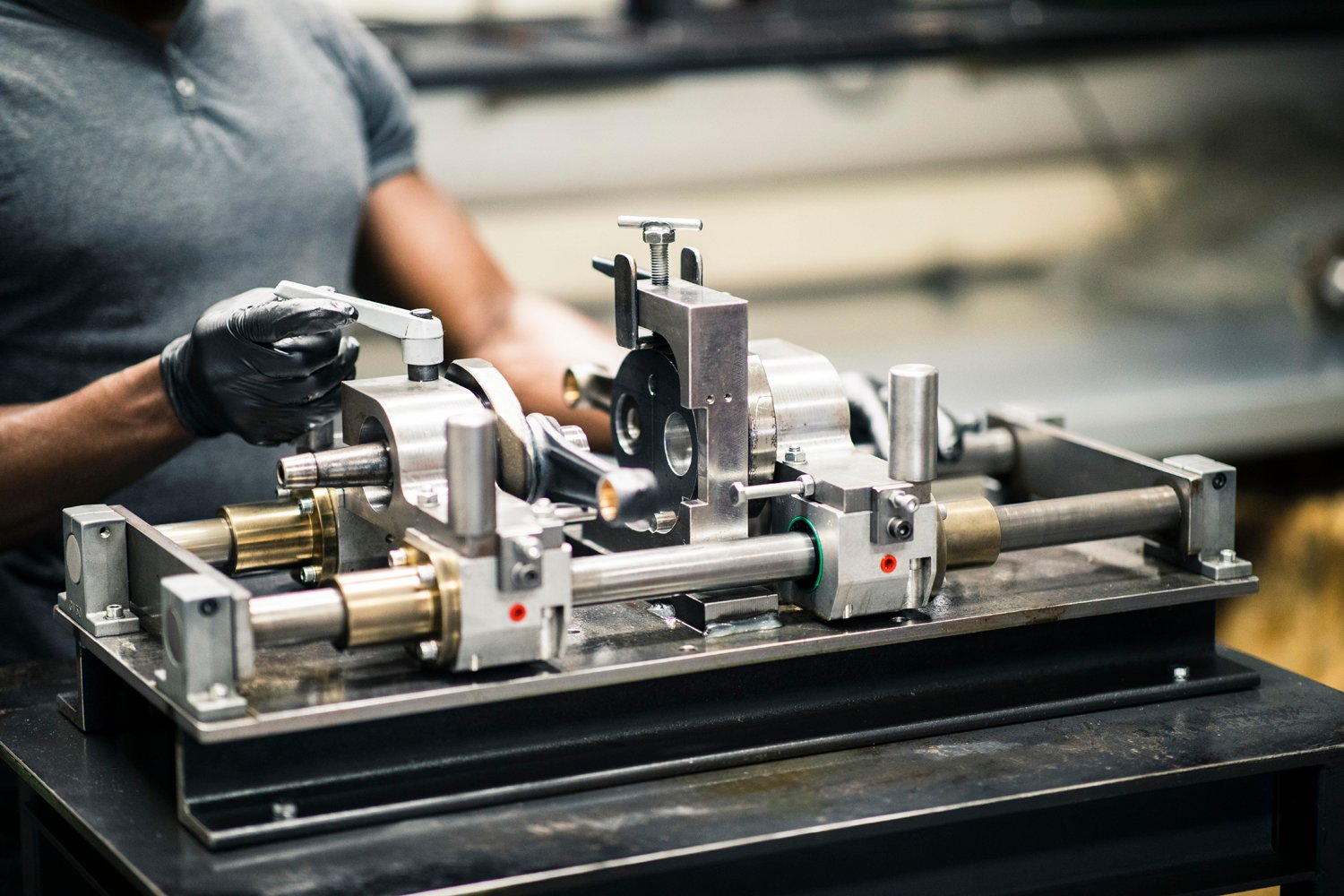

Burton Car Company attaches great importance to the delivery of high-quality products. This also applies to all of our reconditioned parts for the Citroën 2CV. In order to guarantee the quality of our reconditioned parts, they are individually tested. Only in this way can we offer you a plug-and-play product as far as possible, for which we can confidently provide a one-year warranty.

In order to guarantee good quality, we check our engines and carburettors on an engine test bench where they can be tested under all possible loads and revolution counts. This engine test bench is the eddy current type and works by means of electromagnetism. Put simply, it's an electric motor that can provide an opposite torque to the engine. This allows the engine or carburettor to be partially or fully loaded at any desired revolution count. The eddy current brake is water-cooled to prevent overheating. The test bench exhaust is equipped with a Broadband Lambda Probe for checking the petrol/air mixture. The ratio of the petrol/air mixture can be accurately checked using this Lambda probe.

Engines

Testing an engine takes at least 20 minutes and starts with a warm-up phase. During this warm-up phase, the engine is run at approximately 2500 rpm and with a load of 25%. As it warms up, the engine is first checked for sufficient oil pressure and possible leaks. When the engine oil reaches a temperature of 80 degrees Celsius, the most important test phase begins. The engine is briefly subjected to a full load and run through its entire revolution range. During this test phase, the oil pressure, torque, power and petrol/air mixture are closely monitored. On completion of this test phase, the engine is left to idle for a few minutes and is checked a second time for possible traces of oil. Only when the engine is leak-free and meets all of Citroen's specifications does it leave the overhaul workshop. By testing every engine in this way, we can guarantee a high-quality product.

Carburettors

As well as testing every reconditioned engine, we also thoroughly test all reconditioned and new carburettors. The carburettors are fitted to an engine that meets Citroen's factory specifications and is mounted on the test bench. Carburettor testing involves checking that the ideal petrol/air mixture is delivered at each load and RPM. If the petrol/air mixture doesn't meet the required value, it's corrected by adjusting the carburettor jet setting. In addition, the idle speed and the corresponding mixture (CO percentage) are adjusted as ideally as possible. Despite all the checks and any corrections, it may be necessary to readjust a reconditioned or new carburettor after fitting it to your 2CV, Méhari, Ami or Dyane, or to change the jet setting. This is especially true for 2CVs that are equipped with a non-original air filter or Powertube, for example.

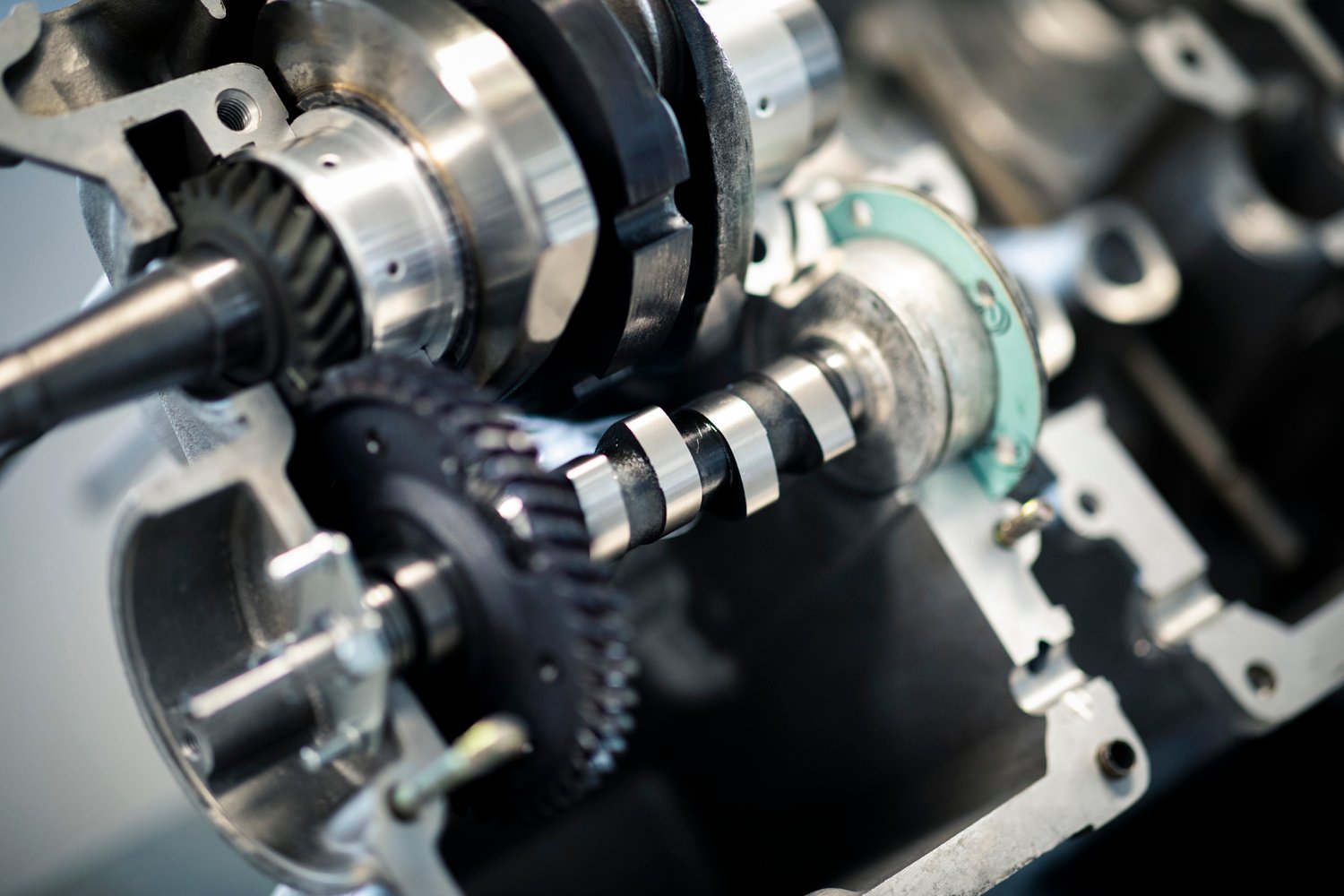

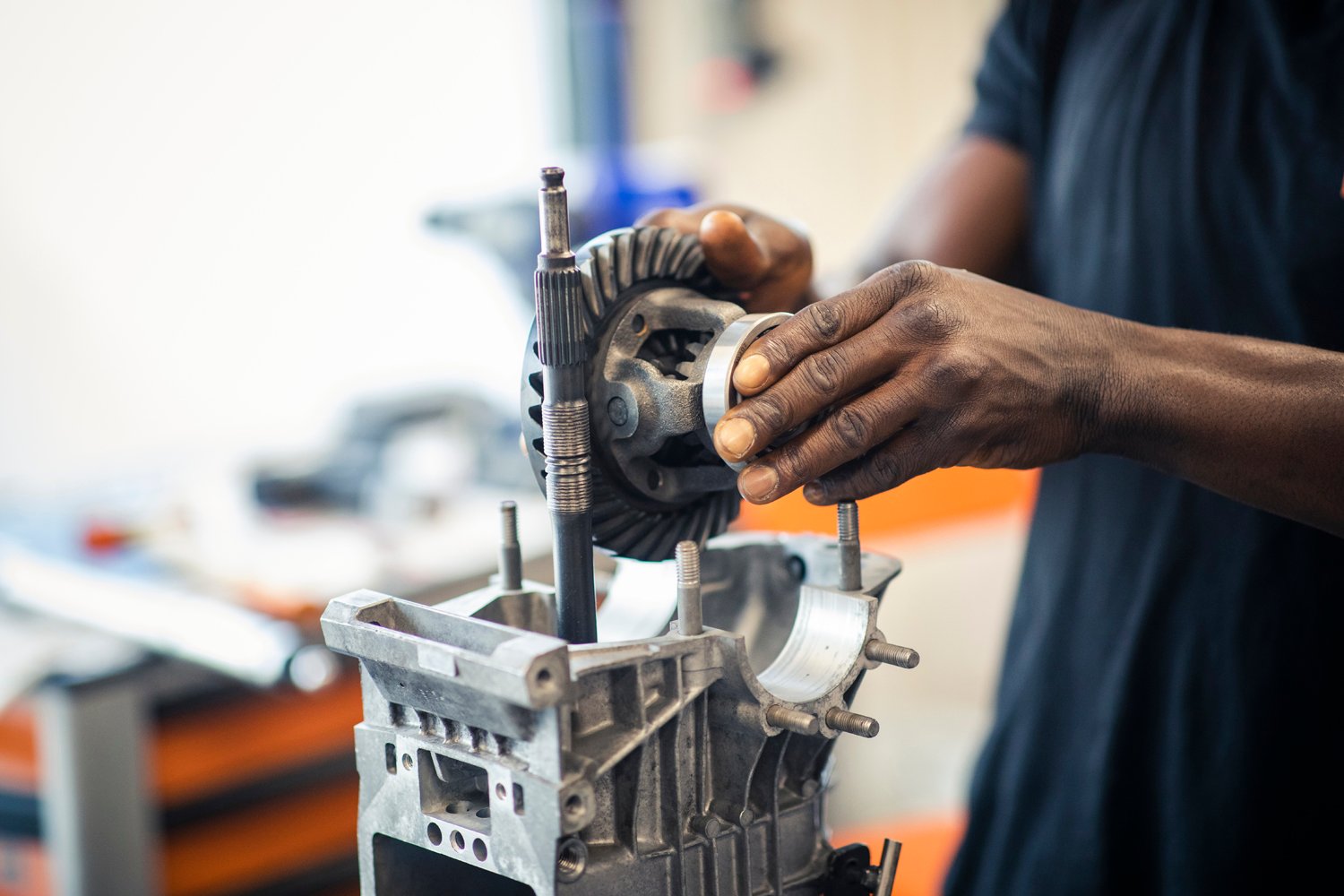

Gearboxes

The gearbox is of course an essential component of the transmission. We try to ensure we have gearboxes readily available from stock. The gearboxes are completely dismantled and then rebuilt with new bearings, gaskets, gears, etc. We have a number of different gearboxes in our range to meet all of your requirements. The gearboxes are equipped according to their original specifications and can be modified upon request. For example, we can opt for longer gears or a limited slip differential.

You are always welcome to contact our overhaul specialists for questions or advice.

Sincerely,

Alex van Mullem

[email protected]

Head of the Overhaul Workshop